Kapmix

Kapmix

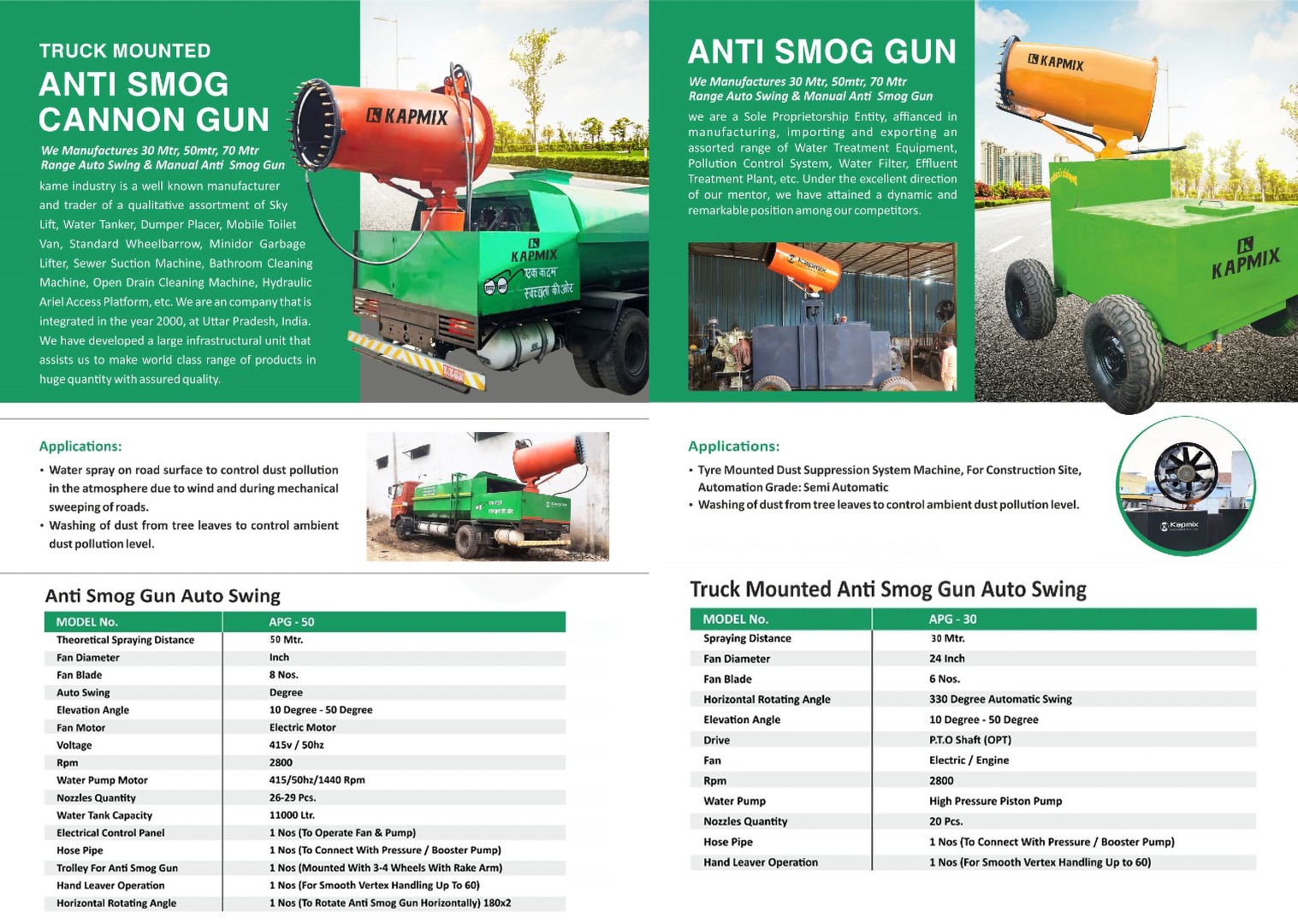

About Kapmix Machinery Private Limited

The Best manufacturer of construction Machine in ghaziabad

Have any custom requirements?

Latest Updates

Read Our Latest Updates & News

×

![]()